AN ISO : 9001: 2015

Certified Company

Have Any Questions?

+91 93720 80617

Write Us At

atlantoent@gmail.com

Certified Company

+91 93720 80617

atlantoent@gmail.com

411 University St, Seattle

Sieves and Screen Testing Kit is available with Densimeters, PIC Gauge, 8X Magnifier with Scale, 50X Pen Microscope with Scale, 30X Magnifier with Torch, Go. No-Go Gauge, 90X Digital Microscope with special measuring software with a complete set of certificates.

Sieves and screen-testing kit are available, which contains Densimeter, PIC Gauge, 8 x Magnifier with scale, 50 x pen microscope with scale, 30 x magnifier with torch, Go, No-Go gauge, 90 x digital microscope with special measuring program is also available with complete set of certificates.

Hand Microscope also known as a pocket microscope, is a device used to check the defects in wire mesh and perforation of sieves and screens. It consists of a LED light to illuminate the observing area and the eyepiece with an adjustable lens to zoom in or zoom out.

In 1874, a Nobel Prize winner named Lord Rayleigh recorded graticular figures which occurred when superimposing very fine grids on top of each other. This optical phenomenon was later designated by the term Moire because of its watermarked effect.

The nominal aperture calibrator is an equipment also known as a Mobile Microscope.

Linear mesh counter or ‘PIC Gauge’ is used to measure wire mesh. Mesh number is determined as number of openings per linear inch.

Pen microscope is a fountain pen type microscope. Bright and sharp images are available from every model, the magnification of which varies from 25X to 100X of which most frequent model is 25X and 50X

Go. No-Go Gauge is a convenient way of measuring perforated sheets (Only Perforated Sheet). It has four measuring sticks with different steps and two Nylon threaded storage round boxes. Our standard Go. No-Go Gauge comes with four measuring sticks. Ranging to measure the perforated sizes from 0.5 mm to 10.0 mm. 0.5 mm, 1.0 mm, 1.5 mm, 1.8 mm, 2.0 mm, 2.2 mm, 2.5 mm, 3.0 mm, 4.0 mm, 6.0 mm, 8.0 mm and 10.0 mm. You can choose the variation of sizes as per your requirement.

The PIN GAUGE is the pin shape fixed size precisely cut cylindrical bars, comes in various sizes. The primary purpose of PIN GAUGE is to measure and inspect the diameter of small holes; it also can be used as a test bar for geometric deviations measurements.

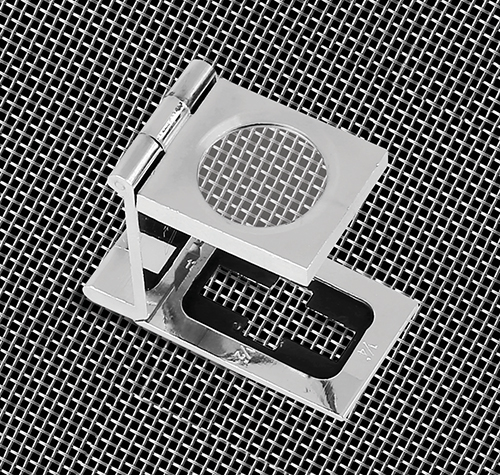

Linear mesh counter or ‘PIC Gauge’ is used to measure wire mesh. Mesh number is determined as number of openings per linear inch. For example, let's discuss about 40#, it is 40 opening in one linear inch. The LMC is having Magnification of 8X. The figure below shows a simple 'Linear mesh counter'.

PROCEDURE OF OPERATION:

The glass or gauge consists of two surfaces on which one side is of magnifying glass and the opposite side is of calibrated scale.

To inspect the wire mesh, place the calibrated scale on wire mesh surface as shown in bellow figer.

Go. No. Go Gauge is a convenient way of measuring perforated sheets (Only Perforated Sheet). It has four measuring stainless steel 316 L quality sticks with different steps and 02 Nylon threaded storage round box. Our standard Go-No-Go Gauge comes with 04 measuring stick. Ranging to measure the perforated size from 0.5 mm to 10.0 mm. 0.5 mm, 1.0 mm, 1.5 mm, 1.8 mm, 2.0 mm, 2.2 mm, 2.5 mm, 3.0 mm, 4.0 mm, 6.0 mm, 8.0 mm and 10.0 mm. The client can choose their variation of sizes as per their requirement. Suppose the client wants to measure 0.5 mm. They have 15 insert the Go-Gauge where the first step is 0.4 mm and then No. Go Gauge. Where the first step is 0.6 mm. If the first step goes into the perforation sheet means the perforated sheet is bigger than 0.4 mm and when the first step of No-Go does not go inside the perforated sheet means the perforated size is smaller than 0.6 mm. assuming it as 0.5 mm.

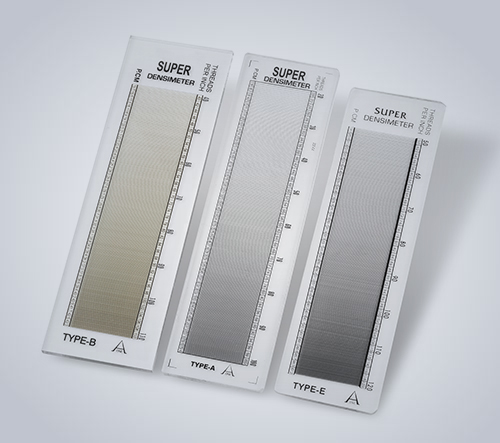

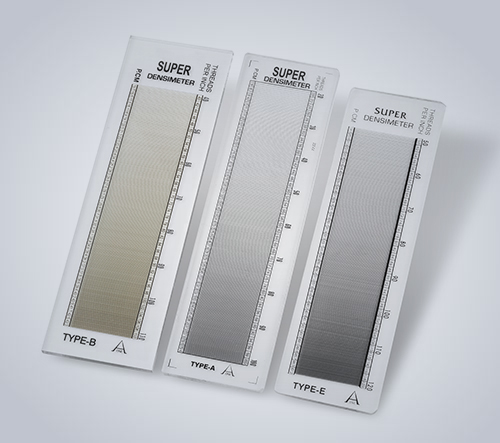

In 1874, a noble prize winner named Lord Rayleigh recorded graticular figures which occurred when superimposing very fine grids on top of each other. This optical phenomenon was later designated by the term moire because of its watermarked effect. The densimeter is a commercial instrument made of artificial glass with etched in grating lines. By placing this instrument on a wire mesh surface, the lines of the instrument are coordinated with the structure of the wire mesh. Super positioning (“interference”) of the two grid systems will be observed. Since the grating of the instrument is one with linearly increasing grid constant, there must be somewhere in this “interference field”, a zone where there is complete harmony of both gratings (wire mesh and calibration lines) The scale beam provided on the side of the instrument, indicates the density value of the grating or wire mesh. The densimeter is used mainly to determine the thread density (set or thread count) on any wire mesh or knitted object having a parallel structure, e. g. a linen weave. For this purpose, the instrument is laid as parallel as possible to the thread (wire mesh) direction to be examined and on top of the sample. An interference pattern will appear immediately, taking the shape of an oval, complete pattern (in the case of parallel grid systems; in a hyperbolic form in the case of radial grid systems). The middle axis of the interference picture is important for an accurate reading of the thread count (number of picks) based on the instrument scales. The number of laterally running threads (warp threads) can also be ascertained in this manner, by slowly rotating the instrument, the moire pattern changes and disappears almost completely at an angle of 45°. On further rotation up to 90° the moire pattern will again emerge quite distinctly and will now relate to the laterally running threads. Measurements can be carried out in daylight without any artificial lighting.

We are working in the format of an outsourcing project office. We assume operational coordination.

Integrating of innovation and public benefit into your workflows; ensuring strategic and sustainable.

We identify the mission, goals and strategic priorities of a business project or non-profit organization.